Vitrolux OEM

Vitrolux systems are forward-looking, reliable, economical, fast and powerful systems. They are characterized by the excellent quality of the created products. Our machines are world-leading in terms of technology.

The ideal laser system:

- Your production lines

- Special mechanical engineering

VITRO OEM SYSTEMS

Internal Laser Engraving - The better solution for product markings

Vitro Laser Solutions UGis one of the world's leading developers, manufacturer and supplier of laser systems for various industrial application areas. Intensive research, permanent quality management and continuous enhancement of laser systems have established us on the international market. Our competence is based on long years of experience.

As world wide technology leader for subsurface laser engraving we have set our attention on the quality and reliability of our high-tech solutions. Vitro Laser Solutions UG is your strong partner combining forwardlooking technology with efficient systems.

As specialist for subsurface engravings, we manufacture reliable laser heads as in-house production. Due to the high vertical range of manufacture Vitro Laser Solutions UG is your specialist for all questions regarding technology, application consulting, system construction and after sales service.

Beside of these complete laser systems we supply you with OEM solutions for individual conversion

Internal engraving process

With the subsurface laser engraving method the surface remains untouched. The desired marking is carried out inside the material, under the surface. Subsurface laser engravings can be made in all kinds of translucent materials e.g. glass, tempered or laminated glass, acrylic glass, ceramic glass, sapphire, polycarbonate etc.

A forgery-proof marking of products has become an essential element of production processes. Most procedures concentrate on the marking of surfaces. A supplementary even coating of the treated surface is difficult. Codings beneath the surface – e.g. Barcodes or a Data-Matrix-Code – break new grounds in the field of fraud resistance and product tracking.

Subsurface engraving by means of laser designed and manufactured by Vitro Laser Solutions UG offers the chance to respond to the requirements of the producing and processing industry flexible and cost-effective. The originally usual marking methods are replaced by a material-free method, which is permanent, non-destructive and fraud-proof.

Vitro Laser Solutions UG is the global leading manufacturer of laser systems for the subsurface engraving. With Vitro OEM systems you are able to produce permanent, abrasion resistent and falsification safe product markings.

Your advantages of internal laser engraving

- No change in the material surface

- Easy subsequent coating

- Ideal for temperature sensitive materials

- Cleanroom capability

- No sand, no processing gas required

- Permanent marking, no changes due to weather, UV-radiation, abrasion

- Contact-free processing

- Even „invisible“ markings possible

- Secure against forgery

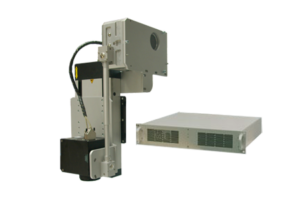

The Vitro OEM systems contains a controller unit, the laser head, the scanner and the lens. Depending on the application, the laser head/scanner/lens unit can be selected in wavelengths of 1064 / 532 and 355 nm.

UV laser mounted on a special machine. A logo is lasered below the surface of swing top bottle caps.

Two OEM lasers mounted above a production line. The lasers run 24/7, around 350 days a year. The logos in the base of the wine glasses can be changed with a mouse click.

The cover with laser protective glass was removed for the recordings.

Two OEM lasers mounted above a production line. The lasers run 24/7, around 350 days a year. The logos in the base of the wine glasses can be changed with a mouse click.

The cover with laser protective glass was removed for the recordings.

UV laser mounted on a special machine. A logo is lasered below the surface of swing top bottle caps.

Technical specifications

Vitrolux OEM

Technical specifications

Laser:

cDiode-pumped, air-cooled Nd:YVO4 laser

other wave lenghts (355nm / 532nm / 1064nm) on request

Pulse repetition frequency max. 8 kHz

Pulse energy dependent on wavelength and frequency used

Laser protection class 4

Optics:

different flat field optics possible e.g. 532nm

f = 108mm, scan field 70 x 70mm in flat glass (optional: f = 160mm, scan field 120 x 120mm)

Time for marking:

Depending on the type and size of the motif

Maximum speed 8,000 points/sec.

Resolution:

Abhängig von Wellenlänge (in nm), Material und Optik

in glass for example

1064nm bis zu 250dpi

532nm bis zu 420 dpi

355nm bis zu 1.200 dpi

Software:

System control via VitroMark software

individual customer-specific solution possible on request

Power Supply:

110-230V/50-60Hz

Optional:

Safety goggles

()* optionally available versions

Laser Room:

„S“ 700 x 600 x 95 mm (BxHxT)

„M“ 700 x 900 x 95 mm (BxHxT)

„L“ 1200 x 900 x 95 mm (BxHxT)

„X“ 1200 x 1400 x 95 mm (BxHxT)

Dimensions of the laser area only apply to class 4 machines!

Laser frequency

The engraving speed at different laser frequencies

See for yourself the progress of the engraving in direct comparison. The time required and the corresponding average number of engraved points per minute are displayed at the end of each engraving.

Matching Videos

Easily explained

Videos about our software and useful How To's about our machines.