Vitrolux Hv2

Vitrolux systems are forward-looking, reliable, economical, fast and powerful systems. They are characterized by the excellent quality of the created products. Our machines are world-leading in terms of technology.

The ideal laser system:

- Single production

- Small series

- Perfect for retail stores

- Compact design

Details about Vitrolux Hv2

Laser technology for diverse interior engraving

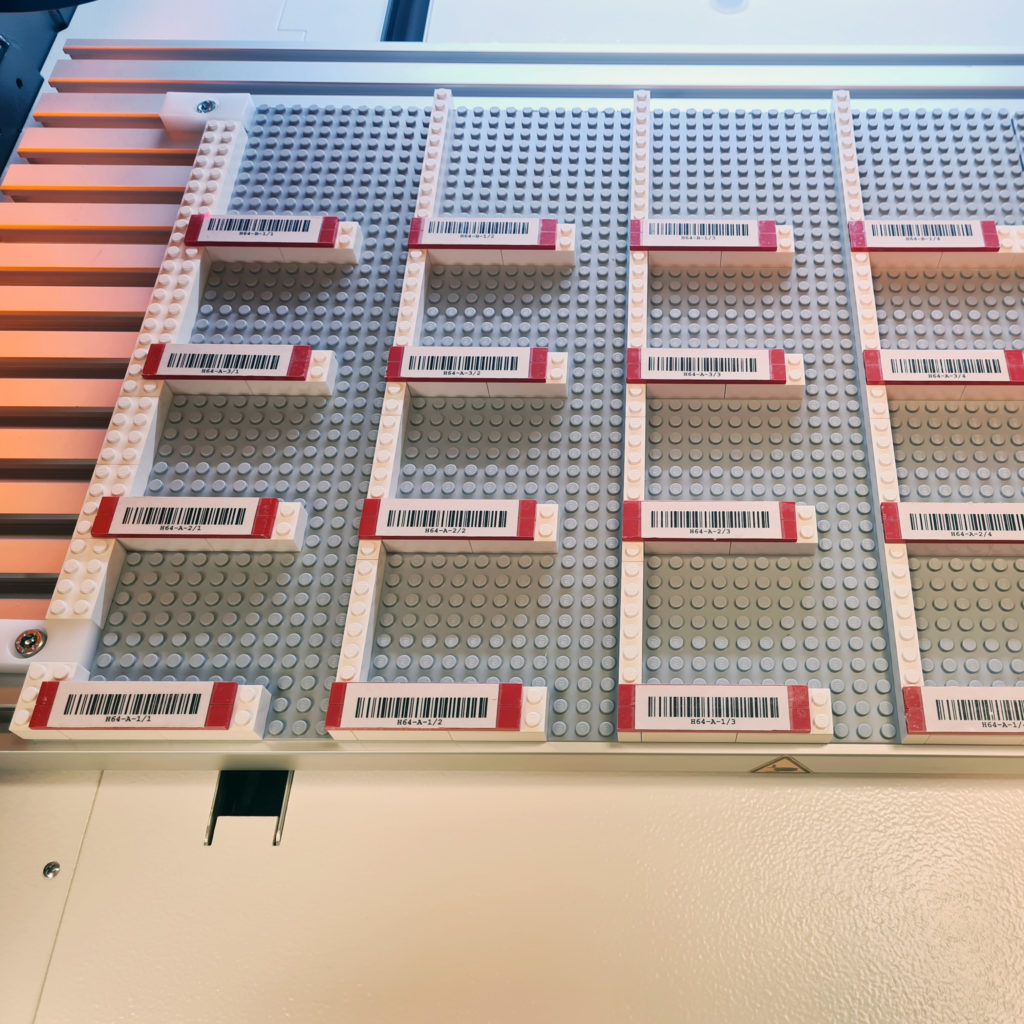

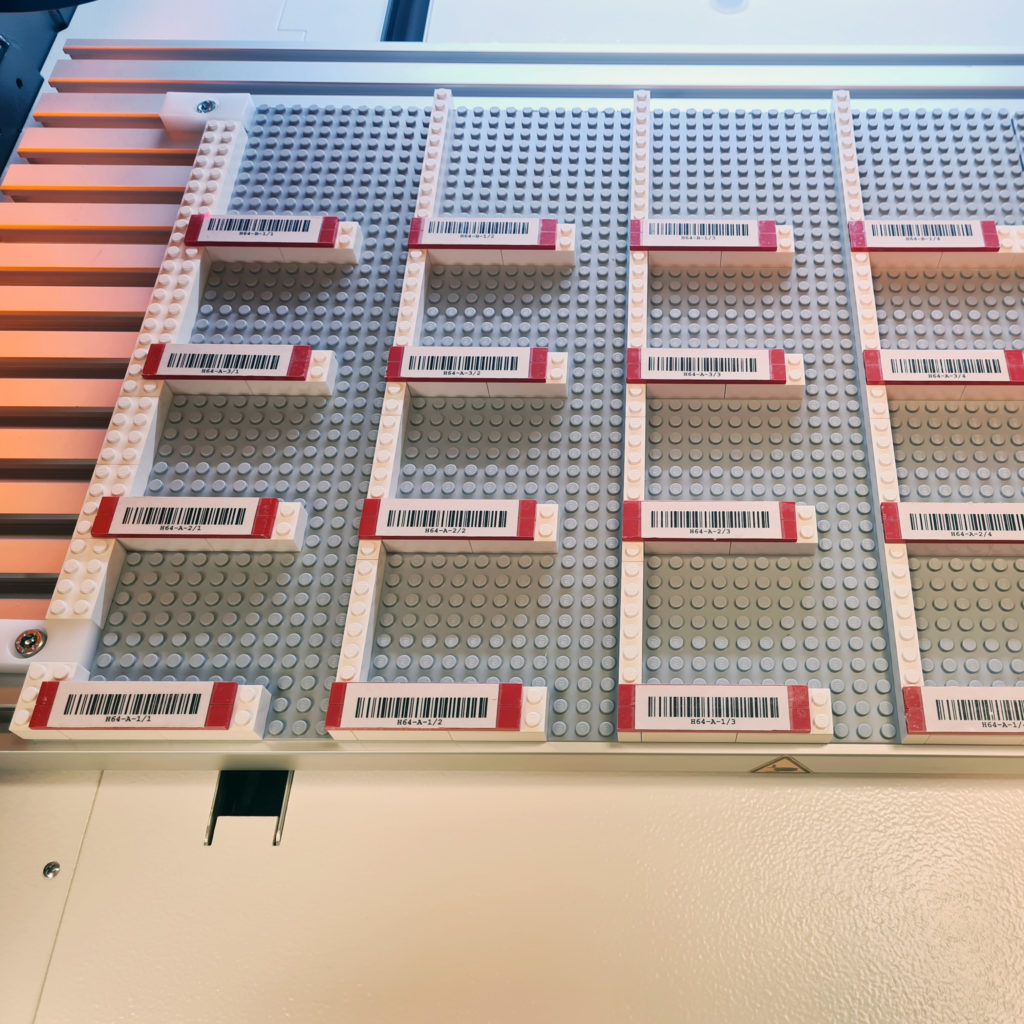

Example of dividing the laser area for individual series production using our database.

Glass sizes up to 80x50mm can be inserted in 16 positions and the corresponding engraving is assigned via a barcode scanner.

However, variable field sizes can also be used - this is what our program function CMP (Customized Mass Production) is used for, which even works without a database.

Details on mass production can be found in the VitroMark software.

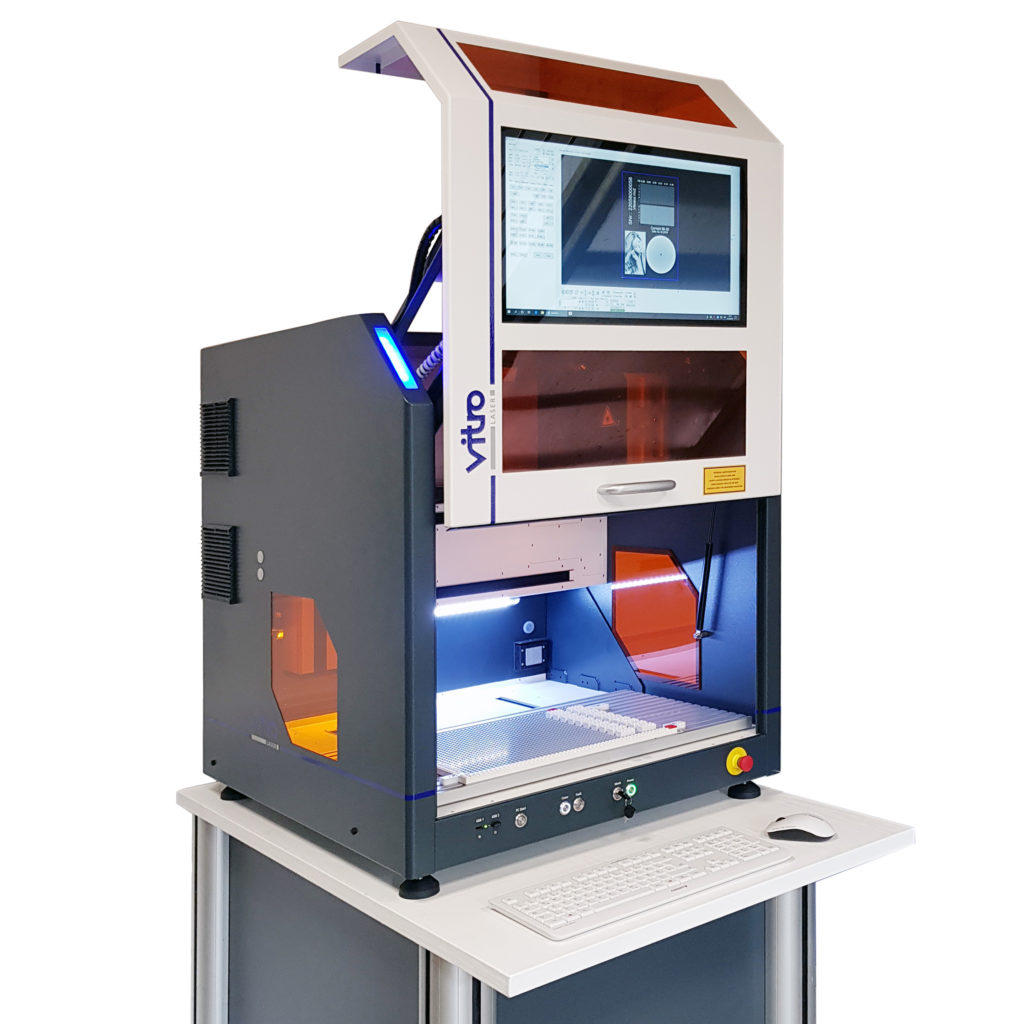

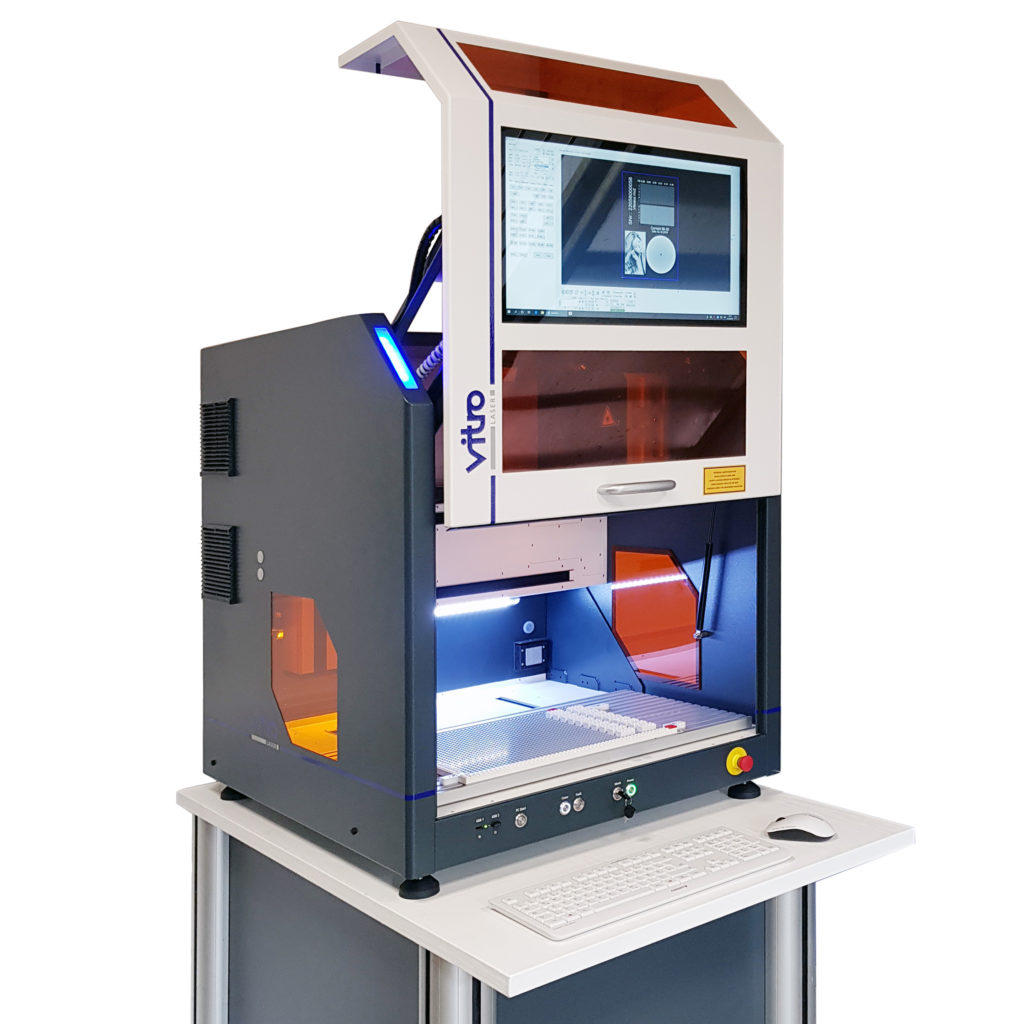

A high-performance industrial PC is integrated into the systems, and a 22′ touchscreen is used as a monitor.

A camera is installed in the interior, which can be used for remote maintenance and can also be output to a separate monitor. For example to show customers the laser process in the shop.

Of course, network and USB connections are also available.

A usefull extra is, that you can lock the door of the Laser. That means, you can lock the Parts of the System that are easily to remove, as Keyboards, and mouse.

A high-performance industrial PC is integrated into the systems, and a 22′ touchscreen is used as a monitor.

A camera is installed in the interior, which can be used for remote maintenance and can also be output to a separate monitor. For example to show customers the laser process in the shop.

Of course, network and USB connections are also available.

A usefull extra is, that you can lock the door of the Laser. That means, you can lock the Parts of the System that are easily to remove, as Keyboards, and mouse.

Example of dividing the laser area for individual series production using our database.

Glass sizes up to 80x50mm can be inserted in 16 positions and the corresponding engraving is assigned via a barcode scanner.

However, variable field sizes can also be used - this is what our program function CMP (Customized Mass Production) is used for, which even works without a database.

Details on mass production can be found in the VitroMark software.

Technical specifications

Vitrolux Hv2

Technical specifications

Laser:

Diode-pumped, air-cooled Nd:YV0₄ laser, wavelength 532nm (1064nm / 355nm)*

Laser frequency:

4 KHz (-8 KHz)*

Optics:

High-performance optics telecentric f= 108 (170)*

Machine:

Laser according to Laser class 1

Software / Hardware:

System control via Vitro VitroMark software

Available Software to create Pointclouds

Vitro Voxelworx for 3D objects with texture

Vitro 2D Pro for flat images with perfect shading and multiple layers

VitroRhinoTools for technical 3D objects with differently defined point densities

Integrated industrial PC with 22′ touch screen

Windows 10

integrated Camera

Power Supply

110-230V/AC, 50-60 Hz

Size of the Machine

790 x 900 x 890 mm (X-Y-Z), weight approx. 215 kg

Laser table:

600 x 370 mm (X-Y)

Laser Room:

400 x 300 x 95 mm (125)*¹ (X-Y-Z)

()* optionally available versions

Laser frequency

The engraving speed at different laser frequencies

See for yourself the progress of the engraving in direct comparison. The time required and the corresponding average number of engraved points per minute are displayed at the end of each engraving.

Matching Videos

Easily explained

Videos about our software and useful How To's about our machines.